Pressures cum Vacuum Relief Valve

These are useful as relief valves for blanketed vessels in which solvents

are filled & drawn out at a high flow rate. These can also be fitted, on

the process vessels to safeguard the process equipment where

unpredicted fluctuations in pressure may occur. By retaining toxic

vapours and avoiding atmospheric contamination these help to provide

increased fire protection and safety. Pressure cum vacuum relief /

breather valves are designed to protect your tanks from possible

casualty due to over pressure created by thermal expansion & product

movement into the tank and excessive vacuum created by thermal

contraction & product movement out of the tank. At the same time, it

minimises costly product evaporation / loss. Continued design

improvements provide these valves with high efficiency, maximum

flow capacity and minimum leakage. These are available "closed end

hoods" type of standard design or with "pipe-away design" for vapour

recovery. These can also be offered as only the vacuum relief valves

with blind flange on pressure port and vice-versa

Breather Valve

Breather Valves, also known as direct acting Pressure/Vacuum Relief

Valves, are special types of Relief Valves which are specifically

designed for tank protection. The range includes pressure only,

vacuum only and combined Pressure/Vacuum Valves, all available with

flanged outlets or vented to atmosphere.

Pressure/Vacuum Relief Valves are used extensively on bulk storage

tanks, including fixed roof tanks with floating covers, to minimise

evaporation loss. The Valves prevent the build-up of excessive pressure

or vacuum which can unbalance the system or damage the storage

vessel.

Pressure and vacuum protection levels are controlled with weighted

pallets or springs and can be combined to provide the required

Pressure/Vacuum settings. It is common to combine pallet and spring

systems in one unit i.e., pressure settings require a spring section,

whilst the vacuum settings use the pallet method.

API Standards are provided as an engineering aid for specification and

selection of "normal" and "emergency" pressure and vacuum Relief

Valves for aboveground liquid petroleum storage tanks. Normal venting

capacity is obtained without exceeding pressure or vacuum that would

cause physical damage or permanent deformation to the tank. The

following will help in sizing a Pressure/Vacuum Valve.

- Normal Relief. The sum of vapor replacement resulting from

emptying or filling and thermal in-breathing or outbreathing.

- Emergency Relief. Thermal out-breathing from fire exposure.

- All Tanks. Generally, require the sizing of a normal pressure and

vacuum Relief Valve to be sized and an independent emergency

Relief Valve to be sized separately.

- Flow Curves. These curves provide pressure and vacuum capacity

which is required for sizing.

OSHA suggest sizing should be in accordance with API 2000. All

requirements are clearly defined in this publication.

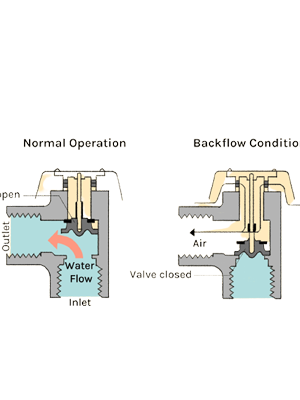

Vacuum Relief Valve

Vacuum relief valves are used in water heater/tank applications to

automatically allow air to enter into the piping system to prevent

vacuum conditions that could siphon the water from the system and

damage water heater/tank equipment. These valves are suitable for

low pressure steam and water service, and are ideal for use in water

heaters and supply tanks, table top heaters, jacketed steam kettles,

unit heaters, low pressure steam systems, and steam coil heaters.

Vacuum Breaker

When a boiler is taken off-line, the steam in the steam space

condenses and leaves a vacuum. This vacuum causes pressure to be

exerted on the boiler from the outside, and can result in boiler

inspection doors leaking, damage to the boiler flat plates and the

danger of overfilling a shutdown boiler. To avoid this, a vacuum

breaker is required on the boiler shell.

Flame / Detonation-Arrestors

A Flame arrestor is a device which allows gas to pass through it. But

stops flame in order to prevent a longer free or explosion.

End-of-line, Vent-to-atmosphere type

Most flame arrestor applications and designs fall into two major

categories. One group consists of end- of – line flame arrestors, also

known as the vent-to- atmosphere type.

In-line, deflagration or detonation type

The other major category consists of in-line flame arrestors, also

known as deflagration and detonation flame arrestors. (Speaking non-

technically, deflagration means rapid burning, and detonation means

explosion.) These units are installed in pipes to prevent flames from

passing.

Most in-line flame arrestor applications are in systems which collect

gases emitted by liquids and solids. These systems, commonly used in

many industries, may be called vapor control systems. The gases

which are vented to atmosphere or controlled via vapor control

systems are typically flammable. If the conditions are such that

ignition occurs, a flame inside or outside of the system could result,

with the potential to do catastrophic damage.

Tank Blanketing Valves

Gas blanketing systems are used to prevent the escape of liquid vapors

into the atmosphere or to prevent moisture from entering a tank and

contaminating its contents. A tank blanketing valve maintains an inert

gas blanket (usually nitrogen or carbon-dioxide) in the vapor space of a

pressure-tight liquid storage vessel. This process is accomplished by

utilizing a steady high-pressure gas source . So that flow is limited to a

constant value when the main valve is opened below the set point. The

valve limits the minimum pressure of the gas blanketing to cope with

outdoor temperature reductions or pump outs without inbreathing air.

When pressure inside the vessel exceeds the valves set point the main

valve shuts off. If pressure increases due to outdoor thermal heating,

or product pumpins, the separate breather valve opens and relieves

the excess pressure.

The valve operates in the closed position whenever the tank pressure is

satisfied of exceeds the set pressure. Whenever the sensed pressure

decreases, the set pressure spring and diaphragm assembly causes a

downward force such that the main valve will open proportionately to

control pressure and limited capacity.

Set pressures are available from 0.50” WC to 3.0 psig. Inlet pressures

range from 20 to 200 psig.

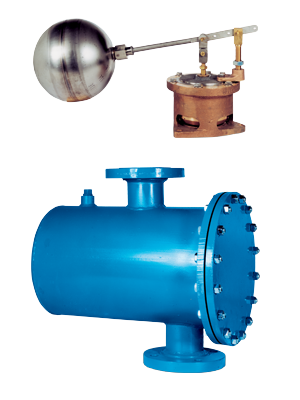

Overflow Trap

Deaerators, tanks with steam blankets, produce additional liquid as the

steam condenses. ASVIN Overflow Trap traps and relieves this

condensate and overflow without the steam blanket

escaping. Buoyancy of its float ball provides force to operate internal

valve assembly to relieve condensate and overflow to drain. Features

steel chamber, brass/bronze internal valve,

316 stainless steel float ball. Sizes 1” through 2” with NPT

connections, and 3” through 6” with 150FLG Large end cover provides

easy access to internal valve assembly. Cover can be tapped for

optional sight glass assembly. Optional sight glass assembly is available

complete with brass ball check, shut-off valves, and drain valves. As

condensate/overflow enters the overflow trap the level of the liquid in

the float chamber increases. For small amounts of liquid, the float ball

lifts the pilot assembly away from the piston disc and the liquid is

relieved through the hole in the centre of the piston disc. For large

volumes of liquid, the piston disc lifts off its seat in the valve body.

The liquid then passes under the piston disc to the drain.

Air Vent (Pressure Relief Vent)

When a boiler is started from cold, the steam space is full of air. The

air can also give rise to corrosion in the condensate system, if not

removed adequately.

The air may be purged from the steam space using a simple cock;

normally this would be left open until a pressure of about 0.5 bar is

showing on the pressure gauge. An alternative to the cock is a air vent

which not only relieves the boiler operator, it will also vent gases

which may accumulate in the boiler.

.png)

Gauge Hatches

ASVIN Gauge Hatch is designed to provide easy access to storage tanks

for gauging product level or temperature and product sampling.

ASVIN Gauge Hatch features a foot opening cover, which provides for

padlocking cover to gauge body. Special cover design prevents

tampering when cover is in locked position.

ASVIN Gauge Hatch is designed to provide easy access to storage tanks

for gauging product level or temperature or product sampling.

Design features include a foot pedal for easy opening, metal-to-metal

seat, self-closing cover, tape gauge marker and eye for suspending

thermometer or a sampler. For mounting, unit can be screwed to tank

nozzle.

Our Products

- Safety Valve

- Relief Valve

- Safety Relief Valve

- Thermal Relief Valve

- Conventional Safety Relief Valve

- Balanced Safety Relief Valve

- Balanced Bellows Safety Valve

- Sentinal Relief Valves

- Pilot Operated Safety Relief Valves

- Rupture Disc

- Tubular Level Indicator

- Reflex Level Indicators

- Transparent Level Indicators

- Magnetic Level Indicators

- Bi-Colour Level Indicators

- Remote IGEMA Level Indicators

- Fullview Glasses

- Ball Flow Indicators

- Double Window Plain

- Double Window Drip

- Double Window Flapper

- Double Window Rotating Wheel

- OPA - Orifice Plate Assemblies

- Restriction Orifice Plate

- Integral Orifice Plate Assembly

- Flow Nozzles

- Flow Venturi

- Pitot Tube

- T Type Strainers

- Y Type Strainers

- Basket Strainers

- Duplex Strainers

- Conical / Temporary Strainers

- Magnetic Strainers

ASVIN

ASVIN